Sheet Metal Parts

NCT Punching

1.The sheet mental parts machining is to process the mental spare parts. It includes some traditional methods and processing parameters, traditional cutting stock,blanking process, bending forming, and also many kinds of cold stamping mould structure and technological parameter.

2.We can accommodate: Steel (cold rolled, carbon steel, galvanized sheet,manganese steel, etc.) Stainless Steel, Aluminum, Brass

3. Finish: Powder Coating, Anodizing, Silk Screening, Laser etching, Zinc Plating, Nickel plating .

4. Various colors: Silver, bronze, black, gold, blue, gray, champagne, red,etc.

5. Machining: Cutting, punching, drilling, milling, bending, welding, CNC etc.

6.Certification: ISO9001, SGS, ROHS, GMC, TUV

7. Strong technical development ability, can provide high intensity and high ductility sheet meatl, to meet customers' different requirements.

8. OEM service available, customized design available

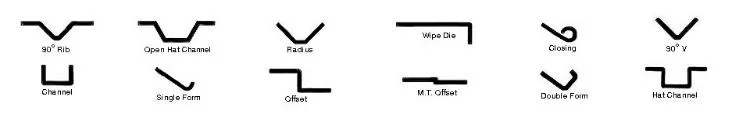

9.Extensive tooling list which offers the ability to form to almost any specification

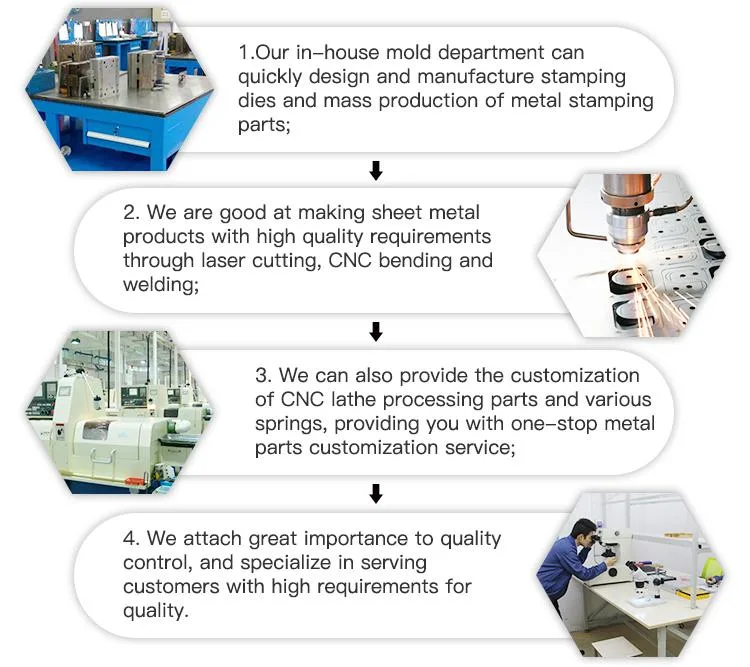

WORKING FLOW

THE MAIN PRODUCTION EQUIPMENT

SOME TESTING EQUIPMENT

How We Cooperate?

1. Client Requirements

We take time to fully understand your requirements.

2. Design Concepts

We provide initial sketches and 3D visuals to ensure we match your needs.

3. Sampling

Making samples provides the opportunity to fully check retail solutions before going live.

4. Design Development

We improve costs and quality by optimizing the sample from structure,material to production processes.

5.Manufacturing

Regular inspections guarantee a quality as specified.

6.Logistics

Properly packing and shipping in time make the goods arrive safely.

Packaging & delivery

1.Packaging details: EPE+Bubble film+Corner protection+paper+plywood+wood strip jointer

2.Delivery date of sample production: about 5 days for sample production after all materials confirmed.

3.Delivery date of mass production: According to the order.

Our Advantages:

1. Strong technical ability, advanced management concepts.

2. Strict product quality control system, for material inspection, process inspection,

shipment inspection, strict control of all processes to ensure excellent quality.

3. Strong sense of service, and timely response to customer requirements.

4. Strong product development capabilities, based on customer requirements to develop a flexible and reliable solution efficient for customers to solve problems, and reduce the costs.

5. Timely delivery.

NCT Punching

1.The sheet mental parts machining is to process the mental spare parts. It includes some traditional methods and processing parameters, traditional cutting stock,blanking process, bending forming, and also many kinds of cold stamping mould structure and technological parameter.

2.We can accommodate: Steel (cold rolled, carbon steel, galvanized sheet,manganese steel, etc.) Stainless Steel, Aluminum, Brass

3. Finish: Powder Coating, Anodizing, Silk Screening, Laser etching, Zinc Plating, Nickel plating .

4. Various colors: Silver, bronze, black, gold, blue, gray, champagne, red,etc.

5. Machining: Cutting, punching, drilling, milling, bending, welding, CNC etc.

6.Certification: ISO9001, SGS, ROHS, GMC, TUV

7. Strong technical development ability, can provide high intensity and high ductility sheet meatl, to meet customers' different requirements.

8. OEM service available, customized design available

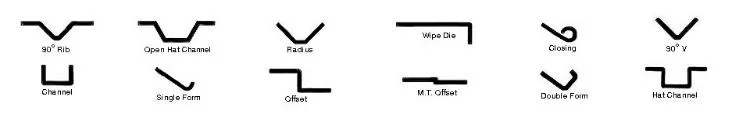

9.Extensive tooling list which offers the ability to form to almost any specification

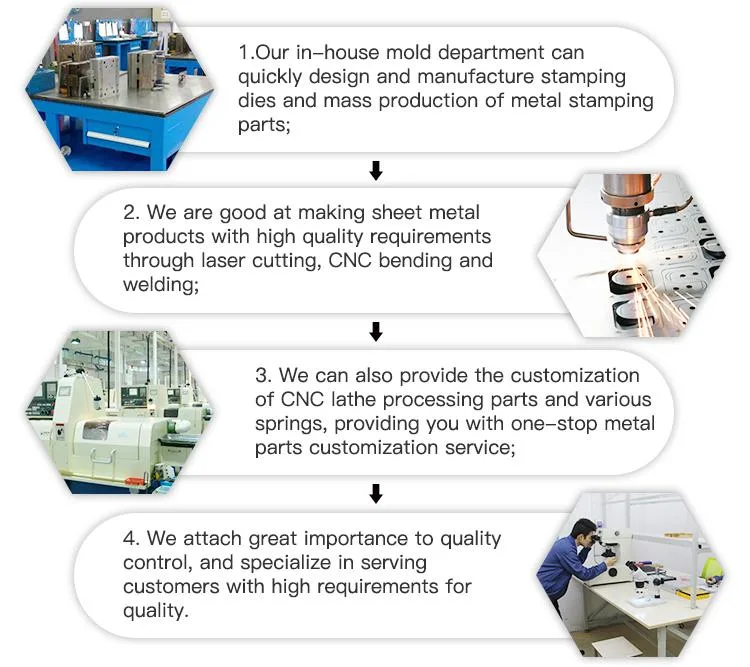

WORKING FLOW

THE MAIN PRODUCTION EQUIPMENT

SOME TESTING EQUIPMENT

How We Cooperate?

1. Client Requirements

We take time to fully understand your requirements.

2. Design Concepts

We provide initial sketches and 3D visuals to ensure we match your needs.

3. Sampling

Making samples provides the opportunity to fully check retail solutions before going live.

4. Design Development

We improve costs and quality by optimizing the sample from structure,material to production processes.

5.Manufacturing

Regular inspections guarantee a quality as specified.

6.Logistics

Properly packing and shipping in time make the goods arrive safely.

Packaging & delivery

1.Packaging details: EPE+Bubble film+Corner protection+paper+plywood+wood strip jointer

2.Delivery date of sample production: about 5 days for sample production after all materials confirmed.

3.Delivery date of mass production: According to the order.

Our Advantages:

1. Strong technical ability, advanced management concepts.

2. Strict product quality control system, for material inspection, process inspection,

shipment inspection, strict control of all processes to ensure excellent quality.

3. Strong sense of service, and timely response to customer requirements.

4. Strong product development capabilities, based on customer requirements to develop a flexible and reliable solution efficient for customers to solve problems, and reduce the costs.

5. Timely delivery.