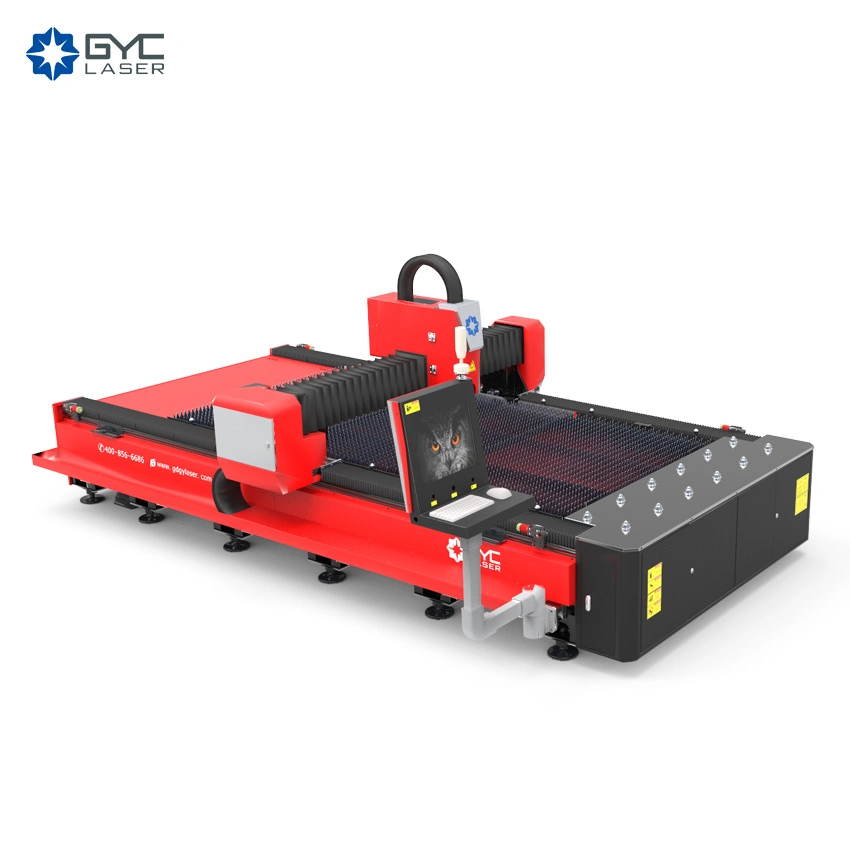

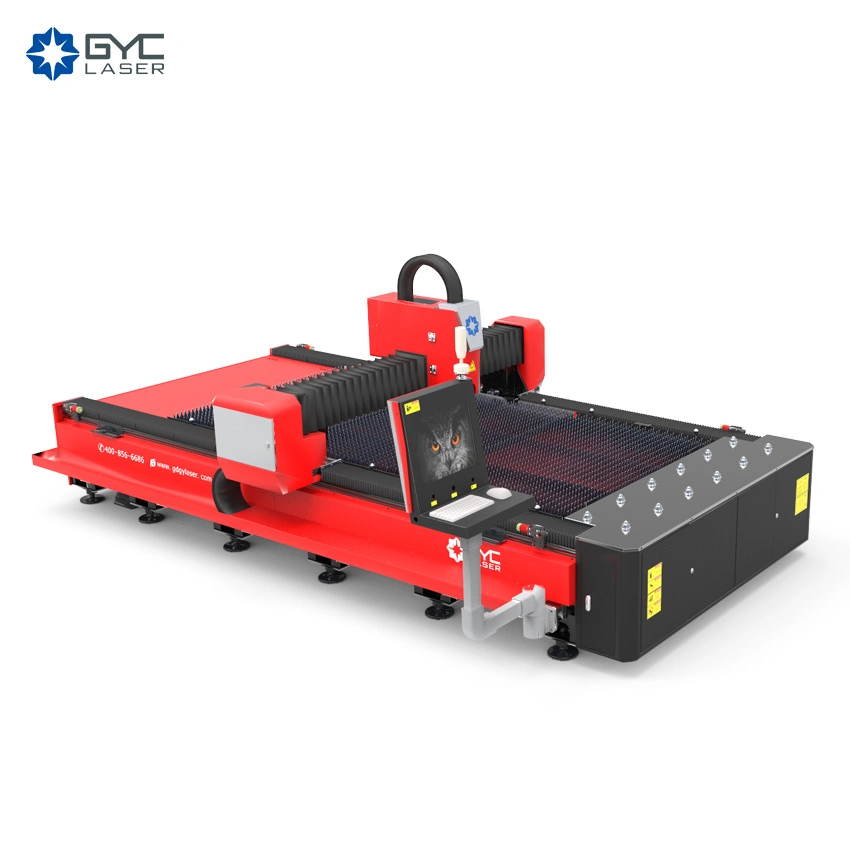

GYC LASER Fiber Laser Metal Cutting Machine

1. Steel plate welded industry machine, 600ºC heat treatment, long life span up to 20 years.

2. Open design, easy loading, and unloading

3. Dual French Schneider servo drive fast speed running

4. JAPAN SMC & AIRTAG Pneumatic components,perfect low pressure Oxygen cutting and high pressure Nitrogen cutting

5. CYPCUT Intelligent control, User friend operating software

6. Aluminum Casting X Axis gantry ensure fast speed and high accuracy.

7. It is driven by world class precision gear rack and linear guide to achieve high precision, high efficiency and stability of the machine.

8. Equipped with the most advanced wireless handheld terminal for remote processing device

SEND INQUIRY NOW TO WORK WITH THE DIRECT LASER MACHINE FACTORY.

FAQ OF FIBER LASER CUTTING MACHINE

For more please visit https://gyclaser.en.made-in-china.com

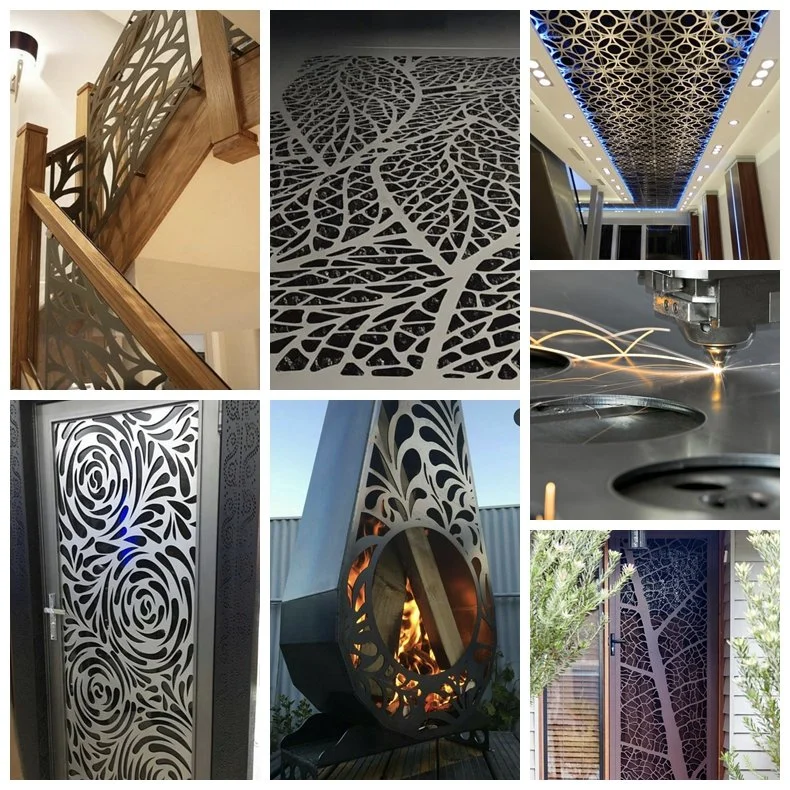

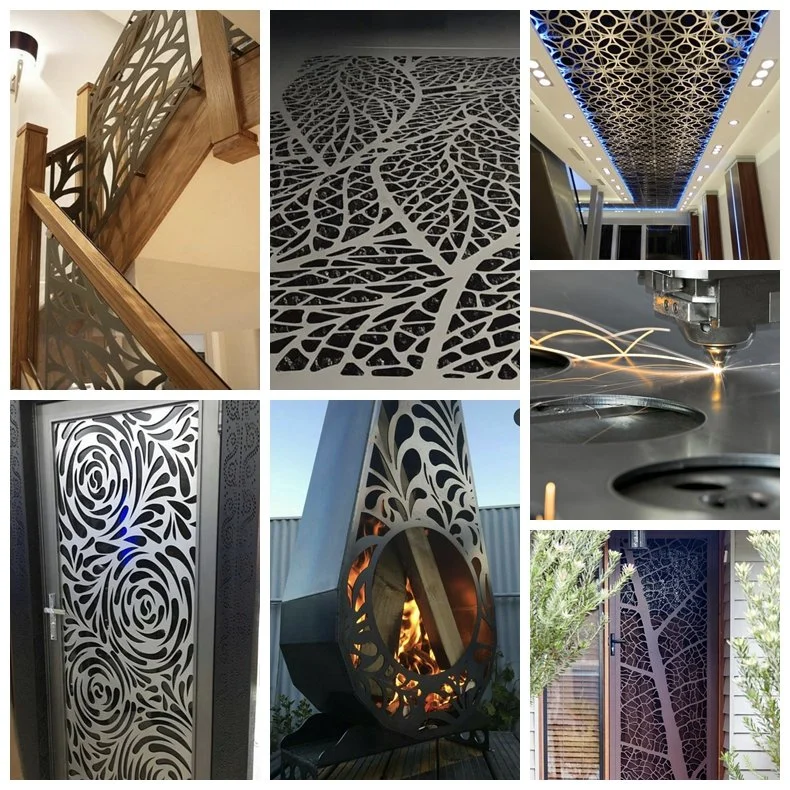

Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

For more please visit https://gyclaser.en.made-in-china.com_cutting

Advantages of laser cutting.

(1) Good cutting quality. The slit width is narrow (generally 0.1--0.5mm) and the surface roughness of the slit is perfect, could be welded without polishing. (2) Fast cutting speed, The heat affected zone is small (3) Environment friendly.

Normally we use Co2 laser 60-150w for cutting nonmetallic materials such as wood, acrylic, leather, fabric etc., if the co2 laser power up to 1kw-5kw it could use for cutting metal too.

And, we offer fiber laser 500w -1.5kw for cutting different metal material, such as stainless steel, carbon steel, Iron, brass, Aluminum etc.

The revenue growth of high power fiber lasers, used heavily in sheet metal cutting, lifted this laser technology to 47% of total industrial laser sales in 2017. Couple this with laser metal cutting representing 35% of all laser revenues, and it becomes obvious why laser metal cutting, a key component in the fabricated metal product sector of manufacturing used throughout the world, is a metric in a country's gross domestic product (GDP)

For the whole project, need to invest for the factory and the infrastructure of the factory, such as the Electricity system, gas system, gantry crane, and the team.

Laser cutting is ok for any design and any thickness metal sheet cutting, it is an ideal for creating shapes with a number of small features, curves and details. Most of the fabrication center we can find both laser machine and CNC punching, sometime not just one.

Operating Cost: Water Jet>Laser>Plasma

Cutting Quality (Result): Plasma>Laser>Water Jet

Precision: Water Jet>Laser>Plasma

Fiber laser cutting:

Is better for cutting metal, Thick steel cost more, High precision.

Plasma cutting:

No matter cutting Thin steel or Thick steel, but cutting quality

water jet cutting:

Almost cut Everything, but very slowly.

And some customer uses it to cut gold, silver for jewelry production.

But we the other options are available.

8500mm*3300mm*18500mm

Temperature of laser source 5-25 ºC, humidity ≤ 70%

We recommend to offer air conditioning to the fiber laser source at least.

Normally we can say as below,

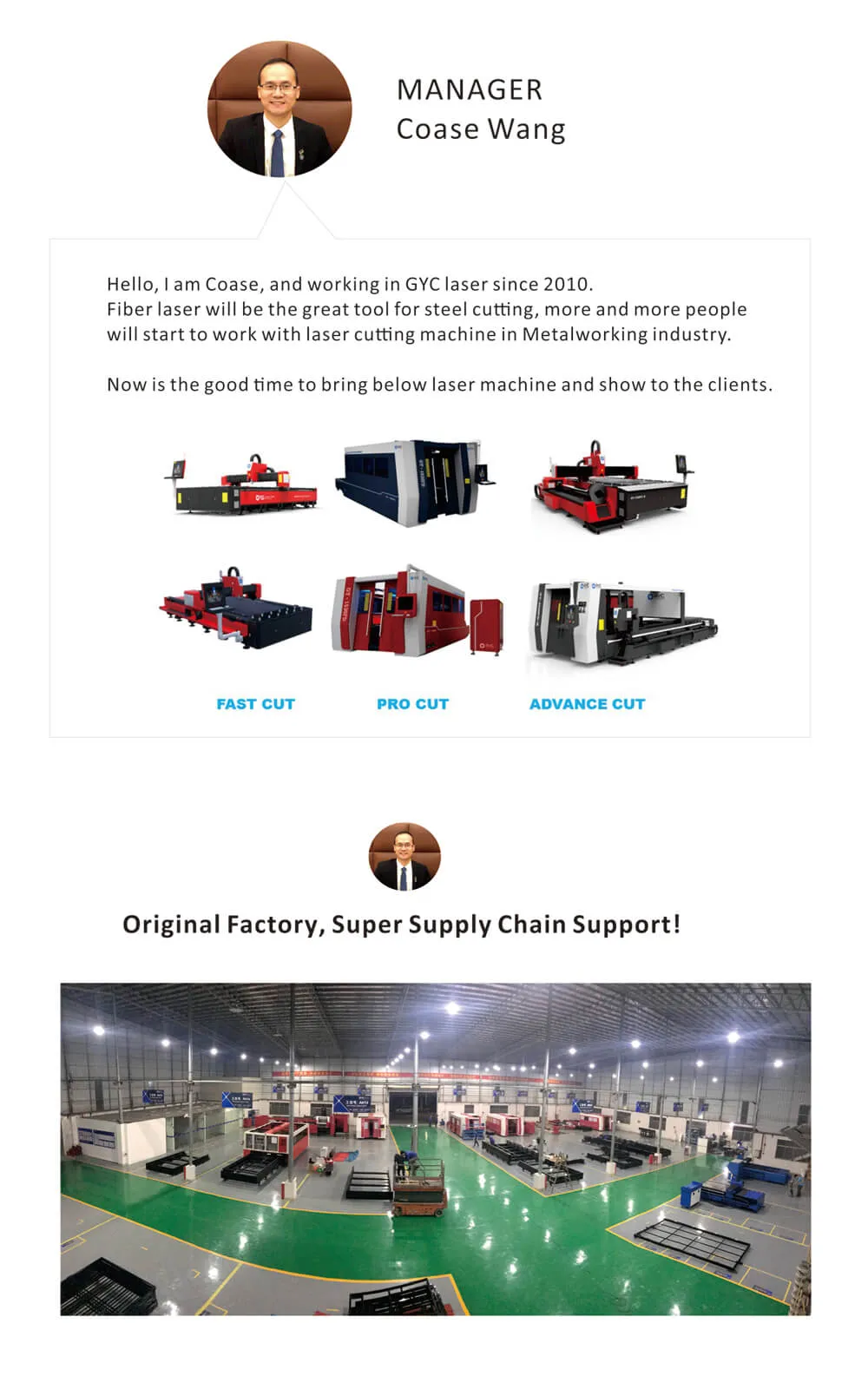

our machine uses the industry lathe, Electronic parts, motors are world top quality, fiber laser source are IPG, RAYCUS and MAX.

welcome to visit GYClaser to check every detail by your eyes.

When it gets damage will need to be changed, depends on the material and the para you use, normally 2pcs Protective lens a week, but when you test new material, the piercing test will damage more protective lens.

Nozzle only when the melt slag stick on the nozzle and make it damage, normally 2pcs a week,

For the ceramic ring only when the laser head hit the table or the steel will make it crack, normally no need to replace, but we recommend to keep on as spares.

Customize is available depends on the MOQ.

Machine software compatible to AutoCAD.

24/7 online service, TeamViewer assistant is available.

Local installation and training are available in your country,

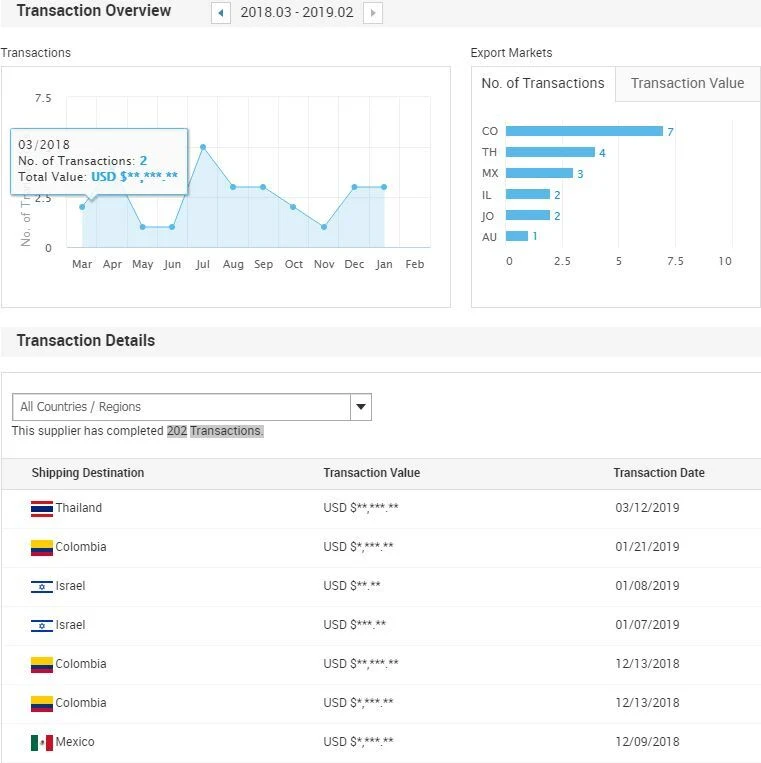

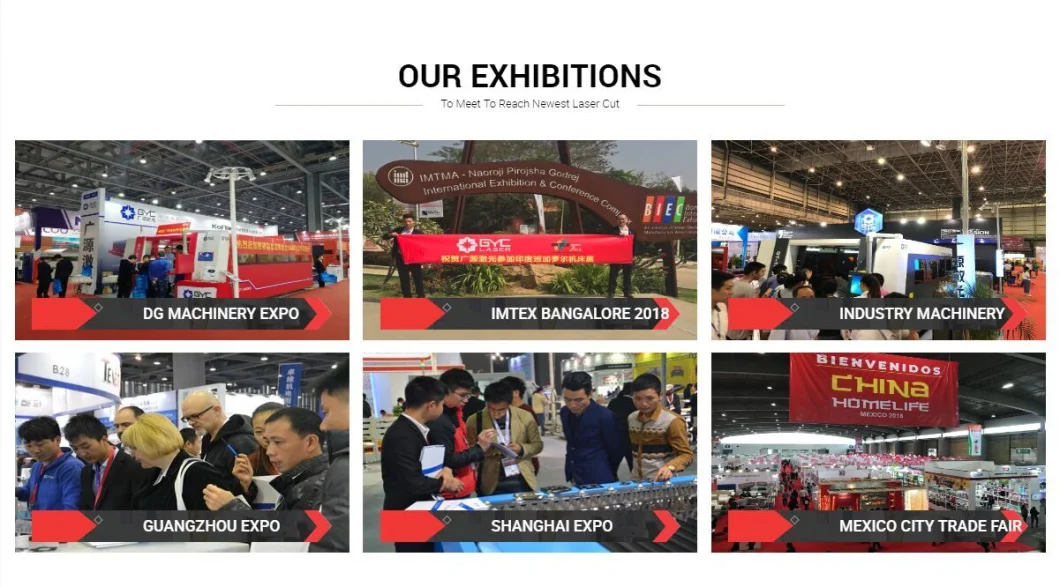

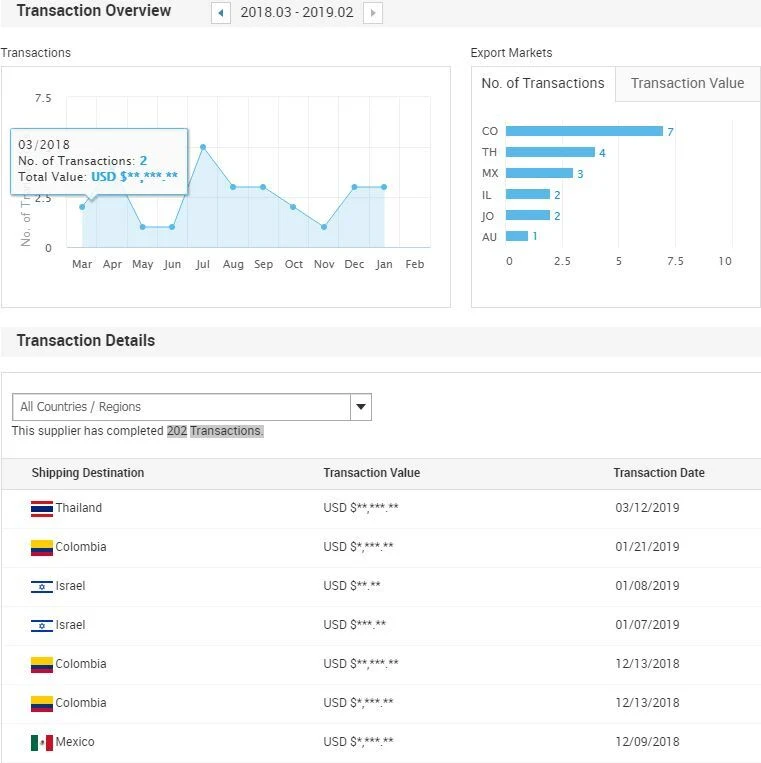

We have local service center in India, Thailand, Colombia and Mexico.

1. The quality of the laser beam- the high-quality laser beam offers high processing precision

2. The stability of Machine bed-heavy machine lathe with top quality servo motor driver and linear guides to make sure machine is stable in fast speed cutting.

The external factors,

1.Materials, even you are cutting the same thickness steel, sometimes different batch steel will get a bit different cutting result, so we need to balance the para to get a perfect performance.

2.Gas, nozzle, protective lens,

The purity of the gas and the stability of the gas pressure have a great influence on the quality of the cutting.

A nozzle if dirty or damage will change the focal length of the beam, which affects the cutting quality. In addition, if the protective lens is not clean, it will affect the penetration of the beam, and lead to a bad cutting.

So, it should be recognized that the accuracy of the laser cutting machine is not only related to the equipment itself, but also to external factors. For Example, the Cutting parameters according to the specific processing materials, the correlation between the laser power, focus position, cutting speed, auxiliary gas etc. And the experience of the operator is also very important.

2. Open design, easy loading, and unloading

3. Dual French Schneider servo drive fast speed running

4. JAPAN SMC & AIRTAG Pneumatic components,perfect low pressure Oxygen cutting and high pressure Nitrogen cutting

5. CYPCUT Intelligent control, User friend operating software

6. Aluminum Casting X Axis gantry ensure fast speed and high accuracy.

7. It is driven by world class precision gear rack and linear guide to achieve high precision, high efficiency and stability of the machine.

8. Equipped with the most advanced wireless handheld terminal for remote processing device

YOUTUBE VIDEO

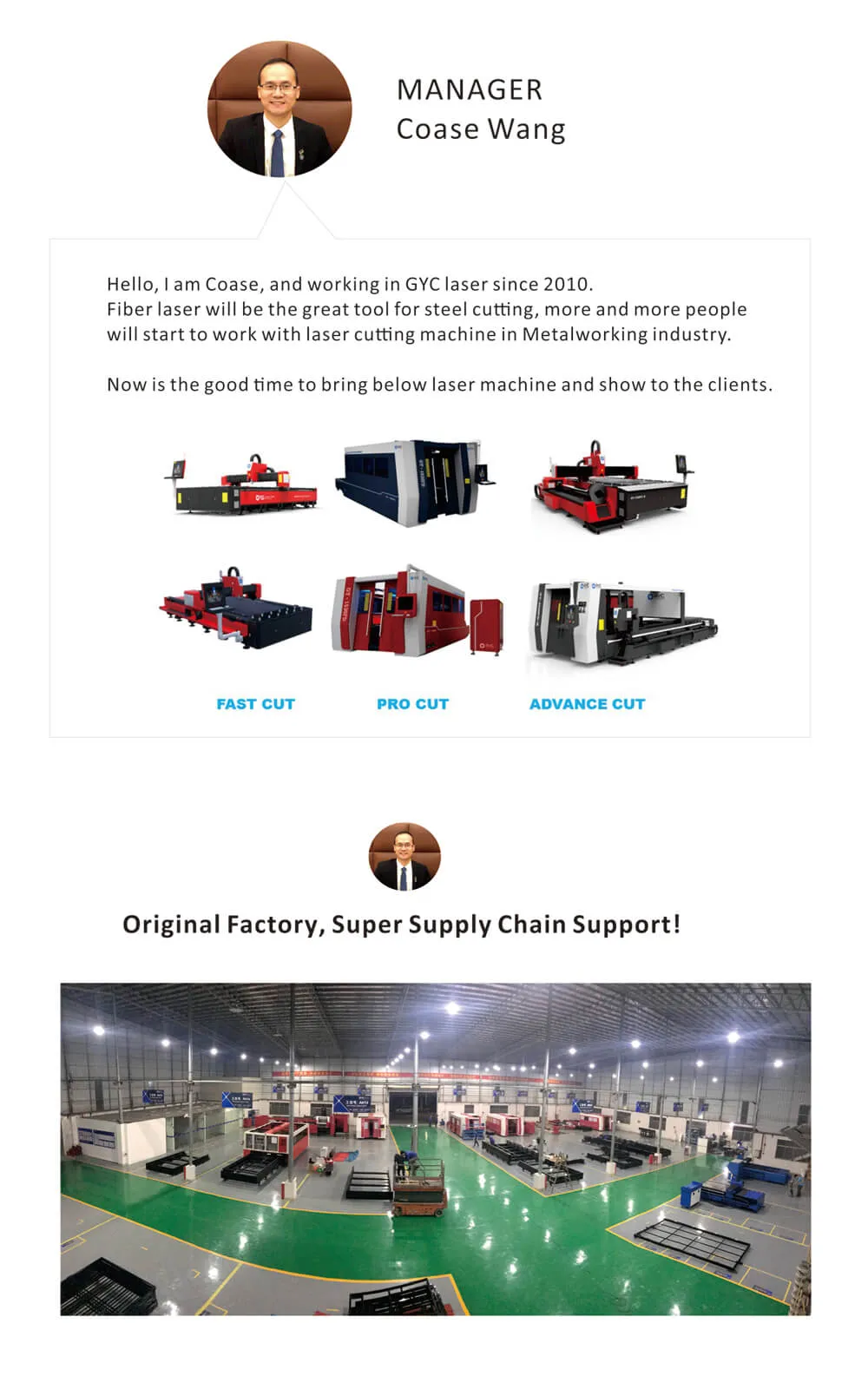

FAST CUT GY-1530FC

https://youtu.be/sA88hkMHrGM

PRO CUT GY-1530FD 1000W AT INDIA

https://youtu.be/8GVgWMkY7zA

PRO CUT GY-2340FD 3300W

https://youtu.be/YeVh_2dEGIE

SUCCESS IN MEXICO

https://youtu.be/MlHzdzBq5Po

ADVANCE CUT GY-1540FD-R

https://youtu.be/U80bZJAzjgQ

FAST CUT GY-1530FC

https://youtu.be/sA88hkMHrGM

PRO CUT GY-1530FD 1000W AT INDIA

https://youtu.be/8GVgWMkY7zA

PRO CUT GY-2340FD 3300W

https://youtu.be/YeVh_2dEGIE

SUCCESS IN MEXICO

https://youtu.be/MlHzdzBq5Po

ADVANCE CUT GY-1540FD-R

https://youtu.be/U80bZJAzjgQ

| Product Name | fiber laser cutting machine |

| Model | GY-1530FC |

| Laser Output Power | 500W/1000W/2000W |

| Working Are(length*width) | 1500*3000mm |

| X Axis | 1500mm |

| Y Axis | 3000mm |

| Z Axis | 100 mm |

| Fiber Laser | IPG/Raycus |

| Max Moving Speed | 80m/min |

| Max Cutting Speed | 25m/min |

| Positioning Accuracy | 0.03mm |

| Repeated Positioning Accuracy | 0.02mm |

| Cooling Type | Water cooling |

| Min Line Width | 0.1mm |

| Drive System | Servo motor |

| Power Allocation | 380V/220V±10%, 50Hz/60Hz |

| Continuous Working Time | 24 hours |

| Weight of Machine | 3200KGS |

| Machine Size (l*w*h) | 4.5*2.6*1.8m |

SEND INQUIRY NOW TO WORK WITH THE DIRECT LASER MACHINE FACTORY.

FAQ OF FIBER LASER CUTTING MACHINE

- What is Laser?

For more please visit https://gyclaser.en.made-in-china.com

- What is Laser Cutting?

Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

For more please visit https://gyclaser.en.made-in-china.com_cutting

Advantages of laser cutting.

(1) Good cutting quality. The slit width is narrow (generally 0.1--0.5mm) and the surface roughness of the slit is perfect, could be welded without polishing. (2) Fast cutting speed, The heat affected zone is small (3) Environment friendly.

- What kinds of Laser in your Machine?

- What is the difference between Fiber laser and Co2 laser?

Normally we use Co2 laser 60-150w for cutting nonmetallic materials such as wood, acrylic, leather, fabric etc., if the co2 laser power up to 1kw-5kw it could use for cutting metal too.

And, we offer fiber laser 500w -1.5kw for cutting different metal material, such as stainless steel, carbon steel, Iron, brass, Aluminum etc.

- How this Fiber Laser cut in Metal?

- Does this kind of laser dangerous?

- Any Radiation from the laser machine?

- How is the market of laser cutting?

The revenue growth of high power fiber lasers, used heavily in sheet metal cutting, lifted this laser technology to 47% of total industrial laser sales in 2017. Couple this with laser metal cutting representing 35% of all laser revenues, and it becomes obvious why laser metal cutting, a key component in the fabricated metal product sector of manufacturing used throughout the world, is a metric in a country's gross domestic product (GDP)

- What about the investment for buying one machine?

For the whole project, need to invest for the factory and the infrastructure of the factory, such as the Electricity system, gas system, gantry crane, and the team.

- What are the advantages of laser cutting compared to CNC punching?

Laser cutting is ok for any design and any thickness metal sheet cutting, it is an ideal for creating shapes with a number of small features, curves and details. Most of the fabrication center we can find both laser machine and CNC punching, sometime not just one.

- What are the differences between Fiber laser cutting and plasma cutting, water jet cutting?

Operating Cost: Water Jet>Laser>Plasma

Cutting Quality (Result): Plasma>Laser>Water Jet

Precision: Water Jet>Laser>Plasma

Fiber laser cutting:

Is better for cutting metal, Thick steel cost more, High precision.

Plasma cutting:

No matter cutting Thin steel or Thick steel, but cutting quality

water jet cutting:

Almost cut Everything, but very slowly.

- What materials can be cut by this Fiber Laser Cutting Machine?

And some customer uses it to cut gold, silver for jewelry production.

- What is the thickness the machine can cut?

- How many options of laser source? What are the differences?

- Any different optional laser heads? What are the differences? auto focus and manual focus?

- which operating software would be used in your machine?

But we the other options are available.

- Dimensions of machine

8500mm*3300mm*18500mm

- How do I choose the machine right for me?

- What are the running conditions of fiber laser cutting machine? Does it require air conditioning?

Temperature of laser source 5-25 ºC, humidity ≤ 70%

We recommend to offer air conditioning to the fiber laser source at least.

- Will there be a lot of dust in the process of using the machine? What we can do for it.

- What is the running cost of the machine?

- Does it require assistant gas for cutting? What is the pressure?

Normally we can say as below,

- Oxygen assistant cutting to get black cutting edge, require pressure 10kgs to cut Carbon steel, mild steel.

- Nitrogen assistant cutting to get white color cutting edge, require 15kgs-20kgs pressure to cut Stainless steel

- Air compressor offer high pressure air up to 16kgs to cut Stainless steel to get brown color edge.

- Does your machine stable to use?

our machine uses the industry lathe, Electronic parts, motors are world top quality, fiber laser source are IPG, RAYCUS and MAX.

welcome to visit GYClaser to check every detail by your eyes.

- What is the life span of the machine and how long is the warranty?

- What are the consumables? and what is the life span of them?

When it gets damage will need to be changed, depends on the material and the para you use, normally 2pcs Protective lens a week, but when you test new material, the piercing test will damage more protective lens.

Nozzle only when the melt slag stick on the nozzle and make it damage, normally 2pcs a week,

For the ceramic ring only when the laser head hit the table or the steel will make it crack, normally no need to replace, but we recommend to keep on as spares.

- Does the machine require on-site installation and training?

- Does the price of the machine include on-site installation, and training?

- How long can I learn to know how to operate?

- What is the voltage used for electricity consumption? Does it need a power stabilizer and UPS?

- Can you provide OEM service?

- What kinds of working areas option of the machine?

- Can I customize the size I want?

- What are the colors of the machine? Can you customize the color we want?

Customize is available depends on the MOQ.

- What is the cutting speed of the machine?

- What is the precision of your laser cutting?

- Which file formats does the machine support?

Machine software compatible to AutoCAD.

- How long is the delivery time?

- What are the payment methods?

- The machine is HUGE, how do we transport it?

- Have you exported to Europe?

- What are the accessories for the machine?

- Which certifications does the machine have?

- Do you have other Metal fabrication machinery such as Press Brake, CNC shearing, CNC punching, etc.?

- What about the after-sales service?

24/7 online service, TeamViewer assistant is available.

Local installation and training are available in your country,

We have local service center in India, Thailand, Colombia and Mexico.

- What are the conditions and processes if I want to be a representative of GYClaser in my country?

- Which industries are the machines suitable for?

- What factors affecting the precision of laser cutting?

1. The quality of the laser beam- the high-quality laser beam offers high processing precision

2. The stability of Machine bed-heavy machine lathe with top quality servo motor driver and linear guides to make sure machine is stable in fast speed cutting.

The external factors,

1.Materials, even you are cutting the same thickness steel, sometimes different batch steel will get a bit different cutting result, so we need to balance the para to get a perfect performance.

2.Gas, nozzle, protective lens,

The purity of the gas and the stability of the gas pressure have a great influence on the quality of the cutting.

A nozzle if dirty or damage will change the focal length of the beam, which affects the cutting quality. In addition, if the protective lens is not clean, it will affect the penetration of the beam, and lead to a bad cutting.

So, it should be recognized that the accuracy of the laser cutting machine is not only related to the equipment itself, but also to external factors. For Example, the Cutting parameters according to the specific processing materials, the correlation between the laser power, focus position, cutting speed, auxiliary gas etc. And the experience of the operator is also very important.